VINCENT: We're close to the coast of Ireland. There's a lot of natural beauty, you see it going to and from work and we'd like to keep it that way. Nice and green, nice and clean.

MICHAEL: I think about sustainability in its broadest sense. We have to look at the three legs of it: environmental, social, and economic. Zero waste to landfill, Led lighting, renewable electricity from the grid, all of that stuff is important, not just for Thermo King Galway, but from a customer perspective as well. And socially in terms of looking after our people - what we’re doing for the community in which we operate.

DAVID: We're very proud of the fact that from 2015, which is eight years now, we are zero waste to landfill. So, we pride ourselves in the segregation of waste on site and we send it to our suppliers and they recycle, reuse, or incinerate.

We were using diesel for years in our assembly lines. So we identified an opportunity to replace that diesel with hydrotreated vegetable oil. We bought a 50,000 liter tank and it's piped into the factory. Converting from diesel to HVO has resulted in a 97% reduction in CO2 emissions.

One of the biggest contributors to carbon emissions is refrigerants. We use about 10,000 tons of refrigerant each month. We've successfully reduced our refrigerant losses by 60%.

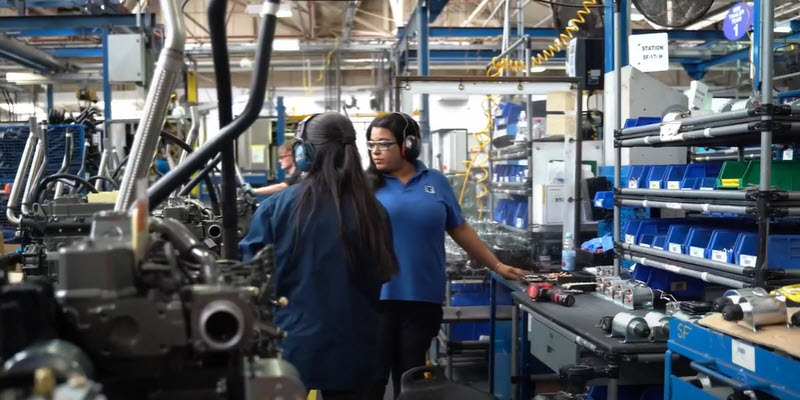

MICHAEL: We were chosen, thankfully, by our corporate leaders to be one of the pilot sites for the Future Factory initiative. We picked the advancer line as the pilot line. So that’s the next step in the electrification of our product range.

DAVID: The Advancer line is ISO 14064 certified. We've successfully attained that standard for the rest of the Galway plant in June this year.

VINCENT: We have an old building here in Galway, and the roof insulation is very poor. We've got a single top skin. We decided to replace that skin with an insulated panel, which means less leakage, less heat loss, and less energy required to heat the plant.

Across the entire factory roof and other buildings on site, we're fitting photovoltaic panels. We estimate that we can generate about 1 million watts of energy every year. Over the year, we expect to generate about 40% of our needs.

MIKE: There is a primary school, a junior school, which is just 300 yards from the back gate of Thermal King. We got a letter from the school asking us if we would support in a small way.

So we got involved with that and we supported and sponsored the building of a sensory room.

For people in the ASD space, it’s very important to have a sensory room. A really small investment financially from a Thermo King perspective, but a huge investment from the school's perspective.

VINCENT: Thermo King Galway has been here a long time. There's generations of family gone through this plant behind me and we're all proud to work here.

MIKE: We're on a good flight path in terms of sustainability. We were on it for quite some time. We're accelerating it now. So it’s exciting times.